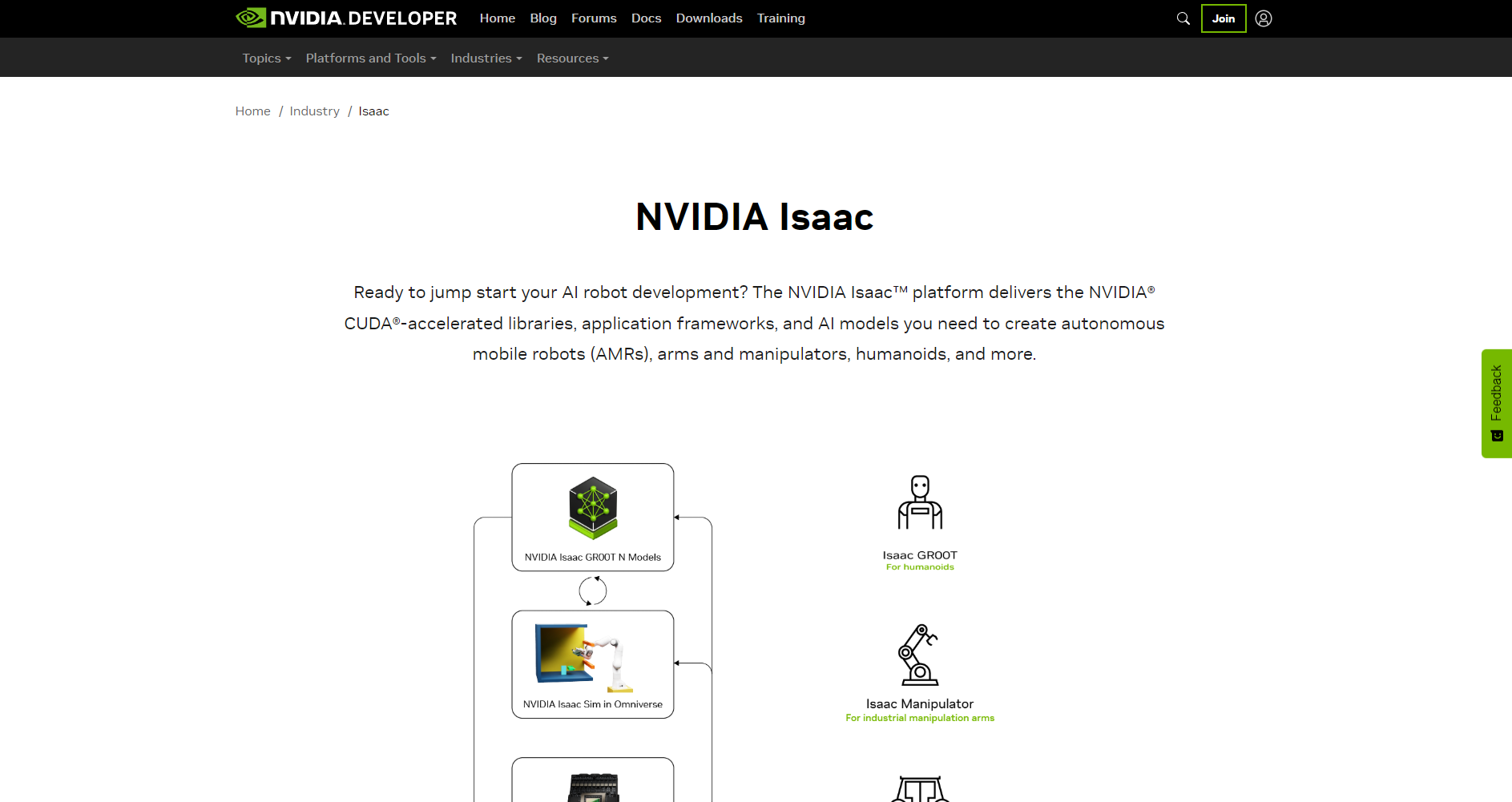

Detailed introduction to NVIDIA Isaac Sim: How to accelerate robot development and simulation testing using NVIDIA Isaac Sim?

NVIDIA Isaac SimIt is becoming the preferred physical simulation platform in the fields of robotics and intelligent manufacturing.Open source, multi-platform expansion, deep AI integrationThese advantages provide the R&D team with high-fidelity physical/visual simulation, automated synthetic data processing, and large-scale testing capabilities.It is highly compatible with ROS and supports training of mainstream models and AI algorithms.The major upgrade in 2024 enhanced batch simulation and cloud deployment, driving a comprehensive revolution in intelligent robots from design to real-world deployment.

I. What is Isaac Sim? An AI Simulation Platform from a News Perspective

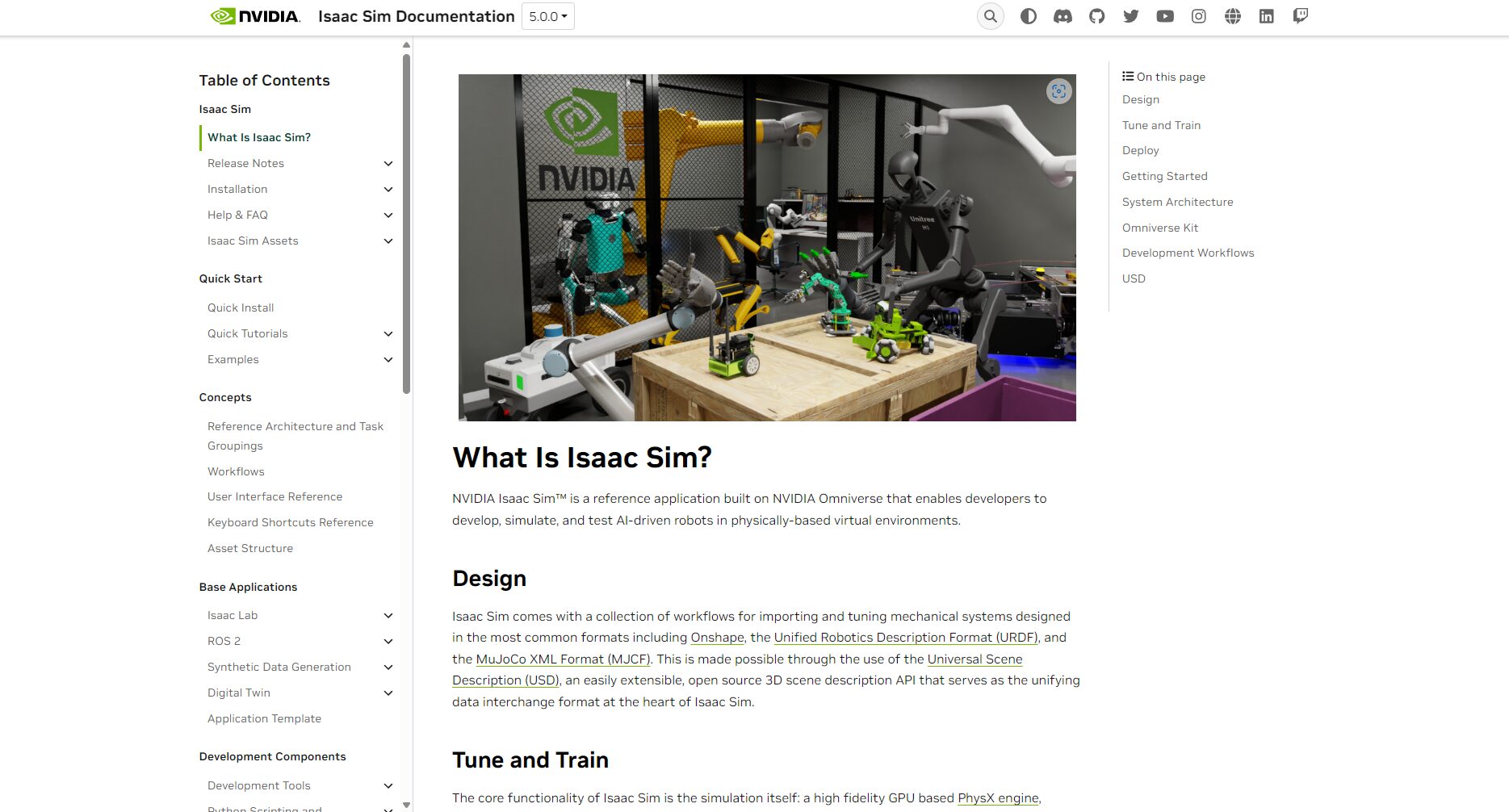

Isaac SimIt is a high-fidelity 3D robot simulation environment launched by NVIDIA based on the Omniverse platform, which hasOpen source, open ecosystemTop-tier capabilities such as multi-physics engine and AI integration. Through integration of mainstream standards (USD, ROS/2, PhysX, RTX(etc.), the platform has gained widespread attention in academia and industry.

- The code is customizable and suitable for in-depth research and development.

- Physics and visuals highly replicate the real world

- One-stop synthetic data to help AI quickly label and train.

II. Core Functional Highlights

| Functional modules | Functional Overview | Leading technology | Related to AI |

|---|---|---|---|

| Physical simulation | Robots highly interact with their environment | PhysX rigid bodies/soft bodies, motor drives | sim2real, end-to-end AI |

| Sensor simulation | Real data from cameras, radar, etc. | RTX rendering, sensor perturbation modeling | Perceptual models and automated data annotation |

| Synthetic data | Batch visual/depth data generation | Omniverse Replicator | AI Dataset Expansion |

| Robot frame integration | Supports ROS/2, URDF, etc. | bidirectional message bridge | Easy migration challenges in real-world deployment |

| AI training interface | Reinforcement learning and motion simulation | Isaac Lab expansion, comprehensive API | One-stop algorithm development and verification |

High-fidelity physical and visual simulationDriven by powerful PhysX and RTX accelerated rendering, physical details such as friction and collision are fully reproduced. For example, the multi-jointed robot performs extremely realistically in complex scenes.

Synthetic Data AutomationOmniverse Replicator enables one-click generation of RGB, depth, point cloud, and fully labeled data, greatly improving the data efficiency of AI models.

| Data types | Support status | Application scenarios |

|---|---|---|

| RGB image | High-precision annotation, diverse lighting | Visual inspection/AI recognition |

| Depth map | Truth-aligned multi-camera | SLAM, segmentation, 3D reconstruction |

| LiDAR point cloud | Multi-line/Disturbance/Motion Blur | Navigation, autonomous driving |

| Split tags | Pixel/Instance Multilevel Separation | Supervised/Automatic Learning |

Deep integration robot development process

It supports existing mainstream robot design standards such as ROS/2, URDF, and MJCF. Through plugins, it achieves bidirectional consistency between simulation and reality, offering flexible workflows and efficient communication. It can be used for laboratory research and can also be quickly deployed to industrial projects.

III. Analysis of Architectural and Technical Advantages

1. Components and Data Flow

| Components | Function Introduction | Ecological integration |

|---|---|---|

| OpenUSD | Mainstream Standards for 3D World Description | Pixar, Adobe, Apple, etc. |

| PhysX Physics Engine | Rigid body, soft body, friction, drive | Engineering, industry, games, etc. |

| Replicator | Batch generation of synthetic data | AI, vision, autonomous driving |

| ROS2/Isaac ROS | Robot communication message synchronization | Scientific research and industry |

| RTX rendering | Real-time high-fidelity ray tracing | CV/AI simulation realism |

2. Three Main Operating Modes

| model | Entrance | Typical User | Advantages |

|---|---|---|---|

| GUI interface | Desktop Apps | Education, verification engineers | Visual drag-and-drop, rapid modeling |

| EXT programming | Python/C++ modules | Research and development, developers | Dynamically expandable, hot-loaded, and highly customizable |

| HEADLESS script | Jupyter/Automation | Algorithms, data generation | Batch simulation, automatic processing |

IV. Industry Applications and Implementation Scenarios

1. Intelligent mobile robots

AMRs, smart factories, warehouse robots, etc., utilize Isaac Sim to achieve path planning, obstacle avoidance, and data tracking in complex scenarios, achieving efficient verification and rapid deployment, becoming an industry benchmark.

- Multiple iterations of obstacle avoidance algorithms based on factory layout ensure accurate and reproducible results.

- Large-scale simulation verification shortens development and testing cycles

2. Autonomous Driving and Intelligent Perception

It can simulate various urban traffic and indoor environments and output multimodal sensor data to help accelerate the safe implementation of AI perception, detection, and positioning algorithms.

3. Humanoid robots & robotic arms

It comprehensively covers multi-degree-of-freedom mechanical motion simulation, reinforcement learning training, and mechanical verification. It is suitable for humanoid robot gait optimization, swarm robot collaboration, and industrial control.

4. Education and Training and Innovative Teaching

The university-wide automation and robotics practice platform, with its rich asset library and intuitive operating system, provides strong support for the cultivation of innovative talents.

V. ISAAC SIM Workflow

1. Importing robot models

| Format | Features | Recommended scenarios |

|---|---|---|

| URDF | ROS/2 standard, structural specifications | Mobile robots/robotic arms |

| MJCF | Suitable for complex designs with high degrees of freedom | Reinforcement learning, physics research |

| OnShape | Direct import of CAD models | Structural innovation, engineering design |

2. Scene & Sensor Configuration

Quickly build 3D scenes using GUI or script drag-and-drop, and flexibly add obstacles, characters, various cameras, LiDAR, etc.

3. Algorithm real-time access and execution

It supports plug-and-play integration of local AI/sensing/control algorithms into simulations, enabling real-time observation and adjustment of the AI decision-making process.

4. Batch testing and data archiving

Large-scale simulation experiments using multiple GPUs in the cloud or locally automatically archive all scenarios and results, providing strong data support for continuous optimization of AI and hardware.

VI. Deep integration with the entire AI R&D process

Isaac Sim has become a "simulation-first base" for AI robot development.“From automatically generating large amounts of synthetic training data to deep reinforcement learning platforms, and then to a closed-loop software and hardware system, the R&D threshold and deployment risks are greatly reduced.

- Large model data supportSim combines AI models such as Cosmos/GR00T to expand data diversity and generalization capabilities.

- Safety closed loop throughout the entire processEnd-to-end simulation-physical verification ensures safety standards for industrial/autonomous driving.

- Direct access to mainstream AI frameworksNo complex adaptation required; flexible algorithm verification and one-click migration and deployment.

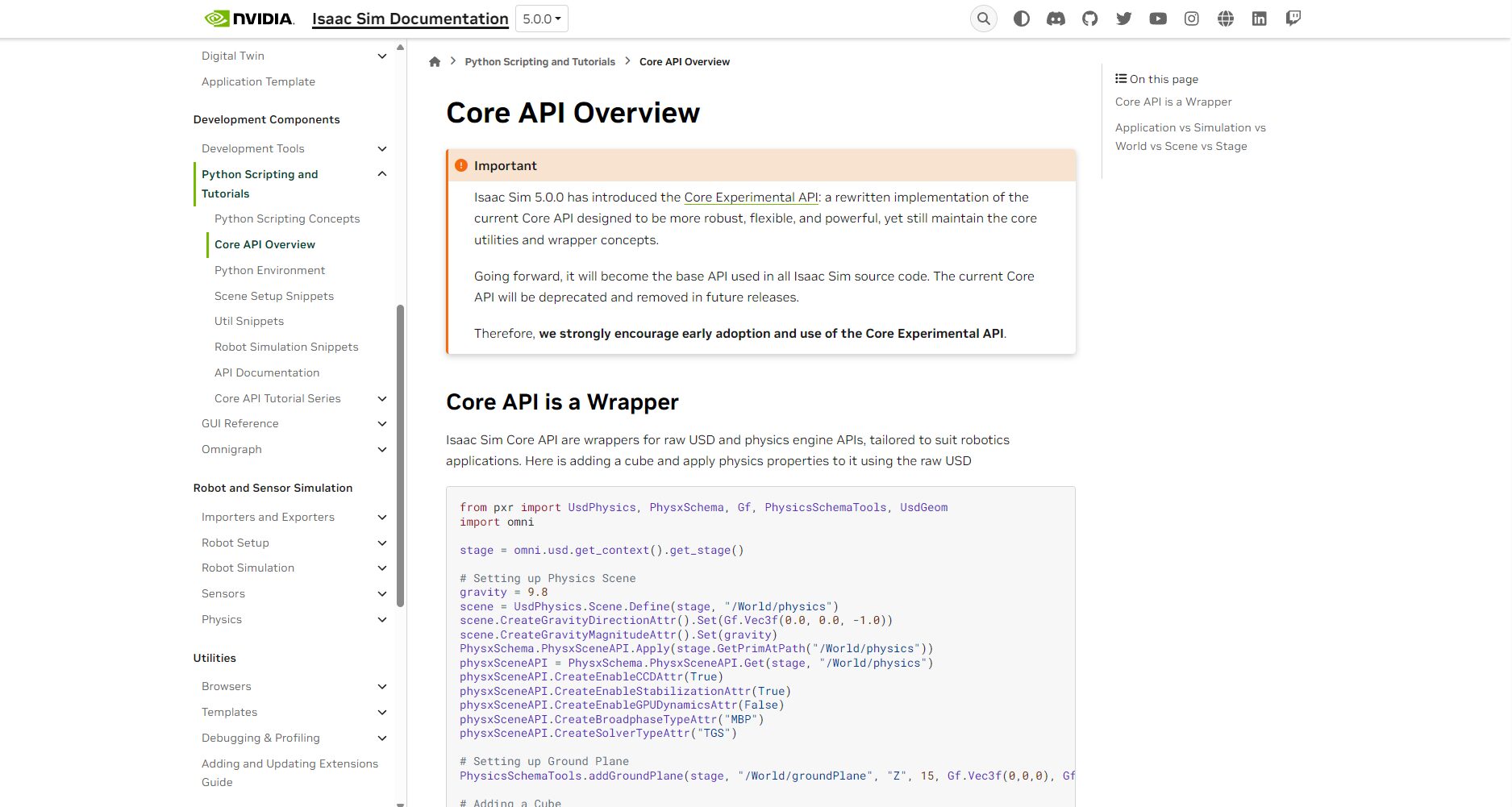

For detailed development documentation, please visit [website address]. API documentation

In this era of rapid innovation in AI and robotics,isaac SIM is characterized by being "open, realistic, scalable, and AI-friendly," driving a paradigm shift in global R&D.In the future, more and more developers and companiesBuilding a "Digital Robotics Lab" using ISAAC SIM“Foresee the arrival of a new era of AI robots that will drive reality and change the world!

© Copyright notes

The copyright of the article belongs to the author, please do not reprint without permission.

Related posts

No comments...